GAMAJET devices use patented technology that combine pressure and flow to create high impact cleaning jets. Cleaning occurs not just where the concentrated stream impacts the surface, but also through the tangential force that radiates from that point and blasts contaminants from the surface, scouring the tank interior.

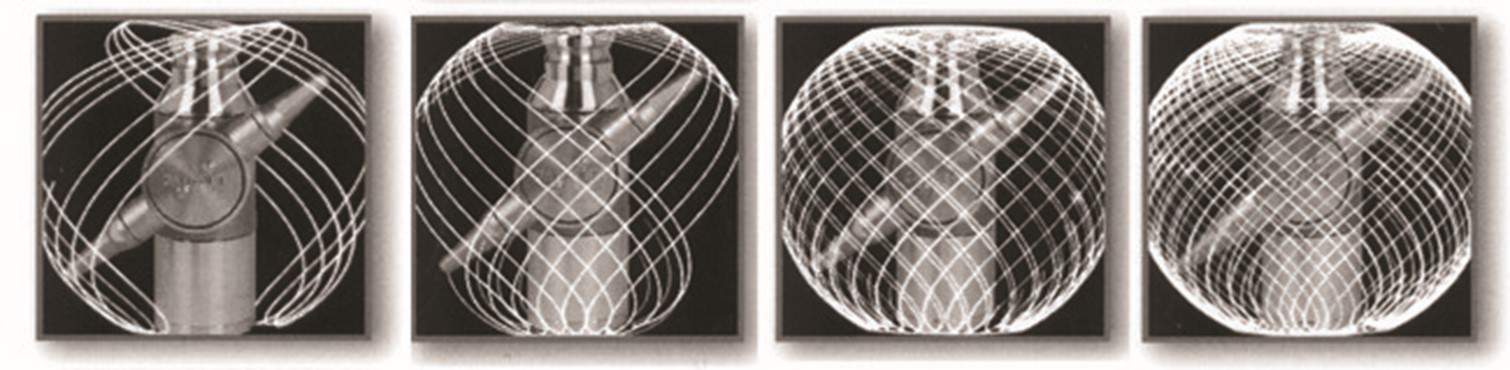

High-impact cleaning jets are delivered in a precise, repeatable and reliable,360° pattern. This combination of impact in a controlled indexing pattern results in an economic ideal, because impact is a one time investment; chemicals, temperature and time are continual, never-ending expenditures.

Force-Alfa Laval tank cleaners are capable of creating up to 85lbs(39 kg)of force at a 25 ft. (7.5 m) distance with minimal pressure and flow. This is impossible with any other technology. Our rotary impingement process is mechanically engineered (gear-driven) to scour every square inch of the tank or vessel in a repeatable and reliable manner.

As the nozzles rotate on a vertical plane, they index two-degrees on a horizontal plane, creating a repeatable and reliable, full-coverage, pattern.

The speed of rotation is mechanically designed into the machine based on pressure and flow.

If pressure and flow remain constant, the cleaning pattern remains constant and the machine cleans in the exact same pattern at the exact same speed, every time.

Wear parts have no effect on this process, making it 100% validatable

Industries we serve

Food and beverage

Wine

Pharmaceutical

Personal Care

Brewing

Industrial Applications

Chemical, paints & coatings

Transportation

Oil & Gas

Ethanol

Pulp and paper